Once upon a time, I was asked to do some work in a customer’s living room.

The majority was simply decorating and the like. But I was also asked to include a couple of more specific projects, one of which was the construction of an in-built book case to the living room.

This would have two main purposes. The first of which is obvious (to hold books). And the second, to bring corner suite away from the window wall thus preventing it trapping the curtains.

Don’t worry, all will be clarified as we go along.

But first let’s take a look at the site for the new book case…

What you see here is the corner into which the lounge suite will be parked. To the right there is a patio door and if you look closely enough, you can see the curtain rail above it. Adding one and one together, you can see how the curtains might look odd in how they would fall behind a sofa.

So the objective for this project would be to build out that corner. Adding more depth to the window reveal and at the same time including some form of bookcase for the client.

So first off…

We added battening to the walls we will be working off.

The uprights to carry the drywall skin and the horizontals to help carry and support the actual bookcase when it is ready to be installed.

Having done all that, the next step was to continue constructing what would be the front of the assembly…

This part of the assembly is the probably the most important as it is going to be ‘load bearing’.

That top horizontal should be perfectly level. And level with the back battening we added to the wall earlier. For it is on these two cross bearers, that we will later sit our bookcase. And remember, a fully loaded bookcase can be extremely heavy. Hence the vertical supports being added below our new makeshift ‘shelf’. (For the want of a better term).

And then, with our bare bones structure in place, we can now disappear to construct our bookcase.

The easiest way to do this is to simply butt our pieces of wood together and screw them into place (as was done here). Or another way is to construct the square box main frame (still jointed as above) and then drill a series of holes for shelf pegs if you would prefer the shelving positions to be adjustable.

In the example I have illustrated, I have used simple white faced MFC (medium fibre composite) board for the construction.

Which is just a posh insider way of saying, ”melamine faced chipboard” (MFC again).

Care must be taken on this stuff when driving in screws… As they can easily pop through the side surfaces if not driven with a certain degree of accuracy. It is therefore strongly advised to drill pilot holes prior to driving in the screws for this reason.

And so, having built the shelving unit, all we need now is a back for it.

For this I opted for a white faced hardboard. This was simply cut to size and nailed onto the back of the shelving unit with ring pins. But before doing that, care has to be taken that you are actually building it square.

It is all too easy to assume that when knocking up a box of equal dimensions it should automatically be square. But that is often far from the case as the illustration below shows. So before adding your back panel to the bookcase, check the diagonals for ‘square’ and adjust it if necessary simply by pushing it back into the right shape. (There should be enough ‘play’ in the joints to easily do this on a ‘box’ this size).

Then once the unit is square, you can fix the back panel.

And with the back panel now fitted…

All that remains, is to lift the newly constructed shelving unit into position. Lifting it onto our previously made sub-structure and centring it as required.

There’s no need to physically fix anything at this stage. As we still need to find the finished surface measurement to properly align it from front to back. BUT… when centring your unit across the front face, don’t forget to allow for the thickness of the drywall (9mm). Which has yet to be added onto the side gable.

And with our bookcase finally in position, all we need to do now is add more timbers to the sub-frame to allow for the fixing of our drywall fascia panels as below.

It is important here that the bookcase still remains movable within its framing.

As we are still not ready to assume a final fixed position (front to back) for our bookcase. But having all our timbers in place now, we are ready to face the whole assembly off. We do this with plasterboard using all of the timber battening behind to screw or nail the facing material onto.

And having faced off the whole assembly. We can now finally adjust the book case into its optimal finished position.

Here we wanted it to sit just a couple of millimetres proud of the plasterboard. To allow for a flush plastered finish. This was done by simply tapping it into position and pinning through it into the surrounding battening behind.

Note too that scrim tapes were added over the drywall joints to prevent them cracking open after plastering. And a metal skim bead was also added to the external corner. This will give it extra strength against any future accidental knocks. As well as a better finish to the corner when plastering. which was to be the next step.

Now our bookcase looks more like an integral part of a solid wall.

It’s beginning to look just as was initially intended. And all that remained to be done was to decorate it along with the rest of the room. Here, we opted for a plain matt paint finish. And because it was going onto bare plaster, I used a ‘contract’ emulsion wall paint which is specifically developed for such purposes.

So with the room now fully painted, all that remains is the addition of cornices to the ceiling (although they were not requested in this instance), skirtings to the floor and an architrave around the actual book case.

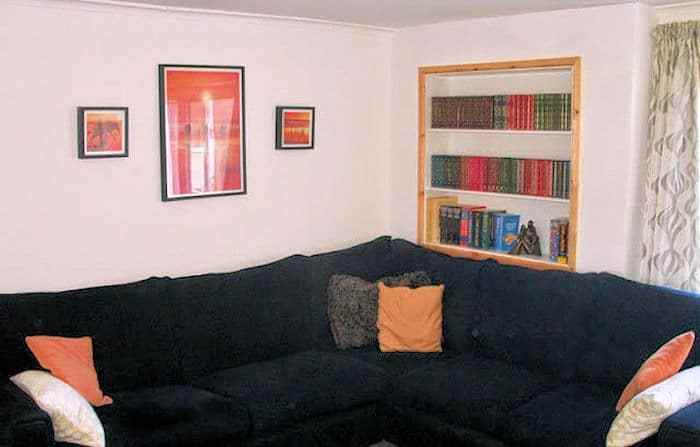

Here it is again, just as was fully intended at the outset.

The bookcase now looking like it always belonged to the room, the curtains no longer being trapped by the suite and still easily accessible above it…

If you would like us to quote for a similar bookcase assembly in your home, simply use the ‘contact us’ form to the top left of this page, or the one on the bottom footer and we’ll get straight on it for you.

© Andy Robinson, Localad Services Handyman Assist

If you have enjoyed reading this article… Be sure to check out my many other Posts. Or better still, for up to the minute notifications of what I am up to, why not subscribe here for free?

Recent Comments